KAROFiX®

Cement-Based Ceramic Adhesive Mortar

Ceramic Adhesive Mortar Used on Vertical and Horizontal Surfaces for Interior

APPLICATION FIELD

- Used for fixing of ceramics and tile coating materials on horizontal and vertical surfaces for interior areas and on floor applications for exterior areas.

- Applied on cement-based plasters on dry and medium wet areas, walls; and on cement-based screed and concrete flooring on floor areas.

REQUIREMENTS

- Prepared easily.

- Provides convenient application thanks to its adequate application and incrustation time.

- Applied on the surface easily.

- Used conveniently on interior surfaces both vertically and horizontally.

TECHNICAL VALUES

| Period for Keeping Uncovered: Tensile Adhesion Strength, N/mm² (after 20 minutes minimum), (EN 1346) | ≥ 0,5 |

| Application Time, Hours | < 2 |

| Adherence Strength / Under Dry Conditions, N/mm² (EN 1348) | ≥ 0,5 |

| Adherence Strength / Under Wet Conditions, N/mm² (EN 1348) | ≥ 0,5 |

| Adherence Strength / Under Hot Conditions, N/mm² (EN 1348) | ≥ 0,5 |

| Adherence Strength / Under Cold Conditions, N/mm² (EN 1348) | ≥ 0,5 |

| Sliding, mm (EN 1308) | ≤ 0,5 |

| Reaction To Fire (EN 13501-1) | A1 |

APPLICATION

SURFACE PREPARATION

- The surface shall always be free of form oil, dust, paint and materials that reduce adherence.

- Repair of the cracks and holes shall be made using appropriate Entegre Repair Mortars before application.

- Application surface shall be dampened with water, if required. PRIMEL 100® shall be applied before application on surfaces that are not resistant to moisture such as gypsum-cardboard plates, gypsum plasters, fiberboard etc. and the fixing operation is started when drying is complete (after approx. 24 hours).

PREPARATION of the MORTAR

- Water shall be put to the mixing vessel first, then KAROFIX® shall be added (5.75-6.25 l water/25 kg bag) and it shall be stirred until the lumps are removed.

- Stop for 5 minutes, and stir again to achieve a homogeneous mixture.

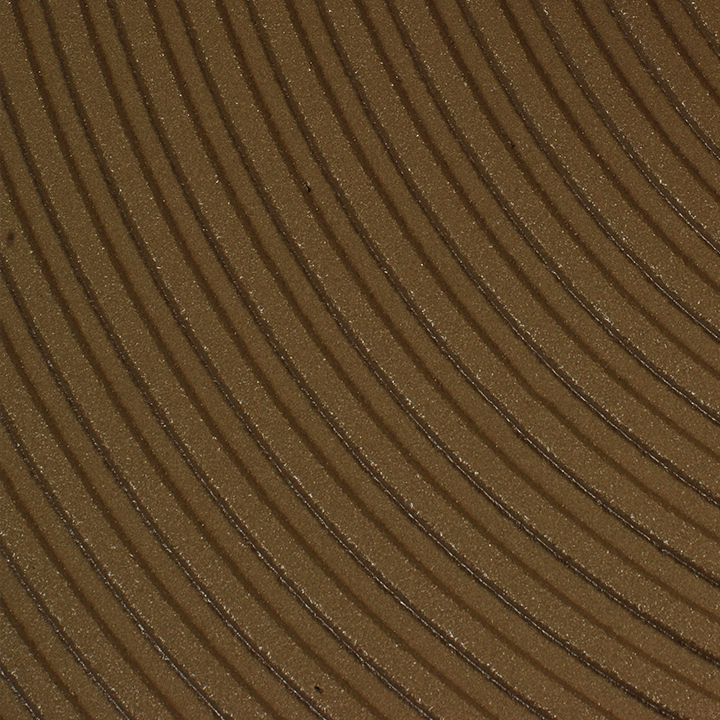

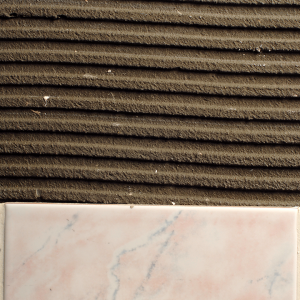

- The mortar prepared shall be applied up to a thickness of 8 mm, it shall be combed and ceramic shall be fixed.

- For a good adhesion, application shall be performed by applying force on the surface with a rubber hammer.

- Double sided fixing shall be used for coatings greater than 1,100 cm².

CONSUMPTION

Applies for application on a single side

| Comb Size | Consumption (kg/m²) |

| 3 | 2-3 |

| 4 | 3-4 |

| 6 | 4-5 |

| 8 | 5-6 |

PACKAGING

25 kg polyethylene-reinforced kraft paper bags

STORING

1 Year Shelf Life*

* If stored in its original package without opening the package under dry, frost free conditions

(1 week after opening the package.)

CERTIFICATE OF CONFORMITY

TS EN 12004-1 / April 2007 / C1T

C1: Normal Hardening Adhesive with Cement

T: Reduced Sliding Properties

Ministry of Public Works Pos. No: 04.013/1

RECOMMENDATION

- No other materials (lime, cement, gypsum, etc.) shall be added to the prepared mortar.

- Mortar shall not be used again by mixing with water or dry mortar if its application time has expired.

- Wait until the ceramic adhesive is dried for joint application.

- Used for coatings with water absorption of > 0.5 (ceramic, tile, etc.).

- Coating areas specified below are suitable for an ideal application:

- On interior floor: Area of ceramics ≤1200 cm²

- On exterior floor ≤900 cm²

- On interior walls: Area of ceramics ≤1100 cm²

- KAROFIX® White is recommended for light coloured coatings.

- We recommend that the application shall be performed between +5°C and +35°C.

- For an ideal application, coating material shall be fixed to the mortar applied on the surface within 25 minutes.

- It shall not be applied on frozen surfaces.

- Do not apply under direct sunlight.

- Do not go beyond the application field and the rules.

- Do not inhale it directly. Wash your eyes with plenty of water in case of contact with eyes, seek medical attention if required.

- For detailed information, please request the safety data sheet.

- Contact us for your technical questions and for your questions about all other application conditions.